How Long Are Hard Hats Good For?

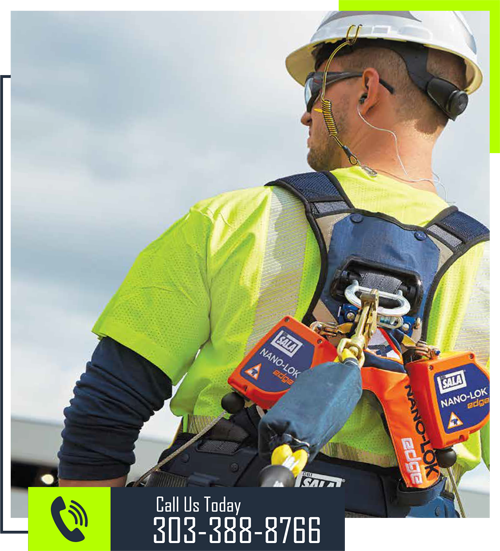

Hard hats are essential in protecting workers from head injuries, particularly in high-risk industries like construction, manufacturing, and electrical work. At Alliance Safety Inc., we specialize in providing personal protective equipment, including a range of hard hats, to ensure workers remain safe from falling or flying objects. While many are aware of the importance of wearing hard hats, there’s often confusion around how long hard hats are good for and when they should be replaced. Understanding the lifespan of your hard hat is crucial for ensuring maximum protection.

How Long Are Hard Hats Good For?

A hard hat is not meant to last indefinitely. The lifespan of a hard hat is influenced by various factors such as wear, exposure to harsh conditions, and the type of work environment. Most hard hat manufacturers recommend a maximum time frame for use, typically between 3 to 5 years from the date of manufacture. However, it's important to note that this is the longest recommended service life, assuming the hard hat has been cared for properly and has not been exposed to extreme conditions.

Workers in industries where hard hats are exposed to direct sunlight, harsh chemicals, or UV damage may need to replace their hard hats sooner. Additionally, the American National Standards Institute (ANSI) and the Occupational Safety and Health Administration (OSHA) provide guidelines to ensure that hard hats provide adequate protection.

Key Components That Affect Hard Hat Lifespan

- Hard Hat Shell: The outer shell is your first line of defense against falling objects and other potential dangers. Over time, cracks, sunlight, and wear can compromise the integrity of the shell. For this reason, most manufacturers advise inspecting the shell regularly for signs of wear, including cracks, breaks, or other damage. If you notice any damage, the hard hat should be replaced immediately to ensure it can continue to protect your head effectively.

- Suspension System: Inside the hard hat, the suspension system is just as important as the outer shell. The suspension straps help distribute the force of impact and absorb energy, protecting the wearer’s head. Over time, these suspension straps can wear out, fray, or lose elasticity, reducing their ability to protect you. It is recommended that the suspension system be replaced every 12 months or sooner if any signs of damage are present, such as damaged stitching or a compromised fit.

Signs Your Hard Hat Needs Replacing

Even if your hard hat has not reached its expiration date, it should be replaced immediately if any of the following are present:

- Cracks or splits in the hard hat shell

- Brittle or worn-out suspension straps

- Signs of exposure to harsh chemicals or UV damage

- Brim or other components that feel weak or flexible instead of sturdy

- Any impact from a falling object, even if no visible damage is present

- Chin straps that no longer secure properly or show signs of wear

Additionally, hard hats expire after reaching their service life, which begins at the date of manufacture. To check your hard hat’s expiration, inspect the inside of the hard hat shell where most manufacturers place a manufacture date stamp. This date helps you determine how long the hat is good for. It's essential to follow the manufacturer's recommended guidelines to ensure that your hard hat continues to provide adequate protection.

Factors That Shorten Hard Hat Lifespan

While the maximum time frame for most hard hats is 3 to 5 years, some conditions can shorten their life considerably. Frequent exposure to the following can necessitate an earlier replacement:

- Direct Sunlight: Prolonged exposure to UV rays weakens the hard hat material, causing it to degrade. Workers who are outdoors frequently, such as those in the construction industry, should inspect their hard hats often for signs of UV damage.

- Harsh Chemicals: Environments where harsh chemicals are present, such as manufacturing plants or laboratories, can degrade both the hard hat shell and the suspension straps, weakening the helmet's ability to protect.

- Extreme Temperatures: Excessive heat or cold can affect the hard hat's materials, leading to cracks or brittle conditions that compromise safety.

Importance of Proper Care and Maintenance

Proper care is essential for extending the life of your hard hat. Regular cleaning with mild soap and water will help remove dirt and contaminants that could degrade the material. It’s also important to store hard hats in a dry, cool place away from direct sunlight and chemicals when not in use.

Do Hard Hats Have an Expiry Date?

Yes, most hard hats come with a recommended expiry date from the manufacturer. This expiry date is typically indicated inside the hard hat and can help workers know when it’s time to purchase a new hard hat. The expiry date is calculated from the date of manufacture and represents the time frame during which the hard hat can provide adequate protection under normal conditions.

However, remember that the expiration date is not the only determining factor for when to replace a hard hat. Regular inspections are vital, as a hard hat can wear out or become damaged well before it reaches its expiry date.

Replacement Frequency Based on Job Type

Workers in different industries may need to replace their hard hats at varying intervals. For instance, employees working in environments with falling objects, high visibility requirements, or electrical shock hazards should follow their industry’s best practices and guidelines for hard hat replacement.

- In the construction industry, where workers face falling or flying objects, hard hats may need to be replaced sooner due to daily exposure to tough conditions.

- Workers in environments with a high risk of electrical shock should consider hard hats with special ratings and replace them according to manufacturer recommendations to maintain optimal protection.

Protecting Workers with Proper Gear

Alliance Safety Inc. is committed to providing top-quality personal protective equipment to ensure your employees stay safe on the job. We understand the importance of having reliable protective helmets that meet ANSI and OSHA standards. While hard hats are designed to provide critical protection, they need to be replaced regularly to maintain their effectiveness.

When purchasing hard hats or any related hard hat accessories, it's crucial to pay attention to the date of manufacture, regularly inspect the helmet for any signs of wear or damage, and replace it as needed. By following proper care guidelines and adhering to industry standards, you can ensure that your employees are equipped with the best possible protection.

In summary, the answer to “How long are hard hats good for?” depends on the working conditions, care, and the date of manufacture. Always be proactive in replacing hard hats when necessary to avoid any possible danger. Alliance Safety Inc. is here to help ensure your team has the protective equipment they need to stay safe.